Composite Longboard

So we used to have a longboard on Putz, until it got hit by a car. Sorry guys.

So we used to have a longboard on Putz, until it got hit by a car. Sorry guys.

The front truck, along with its corresponding chunk of wood, was completely detached from the rest of the body, which also delaminated parts of the plywood on the rest of the deck.

I decided that I was going to cut off all the messed up parts of the longboard, waterjet a replacement part out of aluminum, and then bond them together with carbon fiber. According to a friend, AeroAstro was planning to throw away a bunch of expired prepreg, so I banked on being able to intercept it on the way to the dumpster. As it turns out, this was slightly outdated info, and AeroAstro had already thrown it out a couple of weeks ago. Luckily, he was able to let me use some of the composites in the Unified lab, and I did a wet layup instead. In preparation for all of this, I read through Burt Rutan's composites booklet and watched a couple of surfboard making videos.

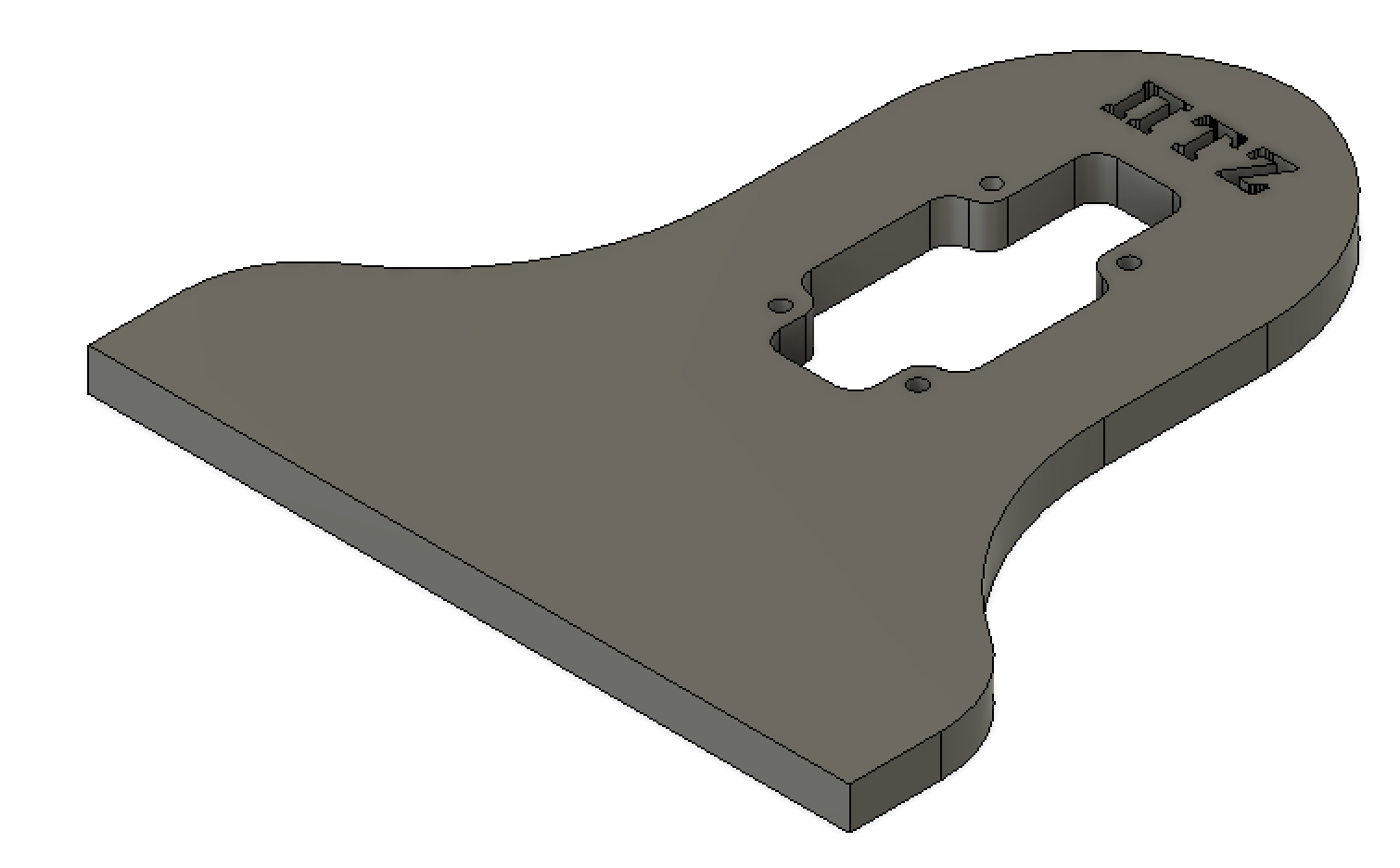

I started by taking measurements off the broken board and made a replacement part, making sure to include space to bond the new part to the board.

After cutting the part, I prepared the board for bonding by removing the paint and grip tape from the wooden section of the wood and by giving both the wood and aluminum a light sanding.

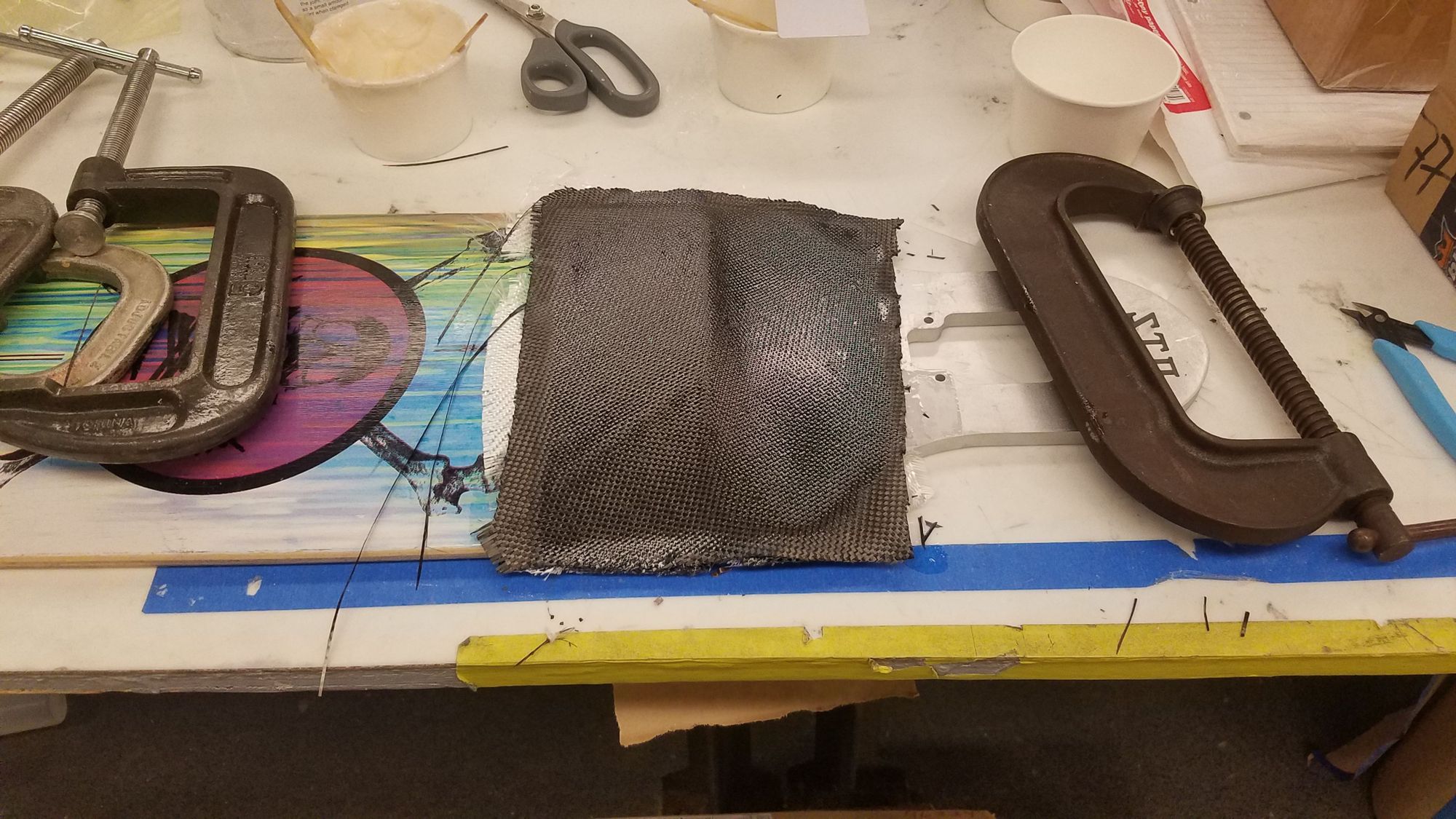

After bringing it to the lab, I cleaned the aluminum with isopropyl and arranged the pieces together. Since the board was curved and the aluminum part wasn't, I needed to smooth out the transition between the two pieces in order to make the layup as easy as possible. I first coated the surface in a layer of epoxy, then used flock/epoxy mixture to create the actual joint. This mixture was made by adding flock until the mixture was no longer "wet." I dumped a blob of this mixture onto the joint, then smoothed it out with a popsicle stick, using the edges of the parts as surfaces to guide the stick along.

I let this cure until the mixture was mostly set, then applied a layer of fiberglass. Carbon fiber directly coupled to aluminum can cause some degree of galvanic corrosion, which can be mitigated by putting a layer of glass in between them. I then laminated another two layers of carbon fiber on top of the glass and left it to cure.

Unfortunately, I was a bit impatient and tried to flip the board over so I could do the other side before the epoxy was hardened. This pulled the two pieces apart from each other, and messed up the flocked epoxy transition from piece to piece. I was able to quickly flip the piece back over and push the flocked epoxy around until the joint looked like it did before, albeit with a gap. This probably ruined the bond between the flocked epoxy and the board, but the overall layup should still be strong enough for its intended use. To cover up all the prints left from pushing the epoxy around, I applied yet another layer of carbon fiber.

Learning from my previous mistake, this was all left to cure overnight. The next day, I filled the gap with flocked epoxy from the other side, smoothed it out, and did a layer of glass and a layer of carbon fiber. Because the two pieces were already rigidly attached to each other, I figured that I didn't have to wait for the flocked epoxy to cure. However, I noticed that I was pushing epoxy out through the fabric while squeegeeing, ruining the smooth transition that I had made. I carefully removed all the excess epoxy from the surface while using my squeegee to reform the transition, and as soon as it looked ok, stopped messing around with it.

The next day, I trimmed away most of the excess carbon fiber with a Dremel using a cutoff wheel, and then sanded the rest away. I blended the carbon fiber into the aluminum and wood using the Dremel, and making sure there were no splinters or sharp edges, sanded it smooth with a random orbital sander.

As it turns out, the carbon fiber is way stiffer and the aluminum heavier than the wood that they replaced, which makes riding the board feel off. Its infinitely more usable than before, but it's w e i r d.

Heard after someone rode it into a filing cabinet:

"That's how they break" - Putzen 1

"No, it's carbon fiber" - Putzen 2