Chuck Jaw Replacement

You break it, you fix it.

One of the jaws in the MITERS Hardinge's 3 jaw chuck has been missing a couple of its teeth for a while, and recently stopped engaging well with the scroll after I broke off another.

You break it, you fix it.

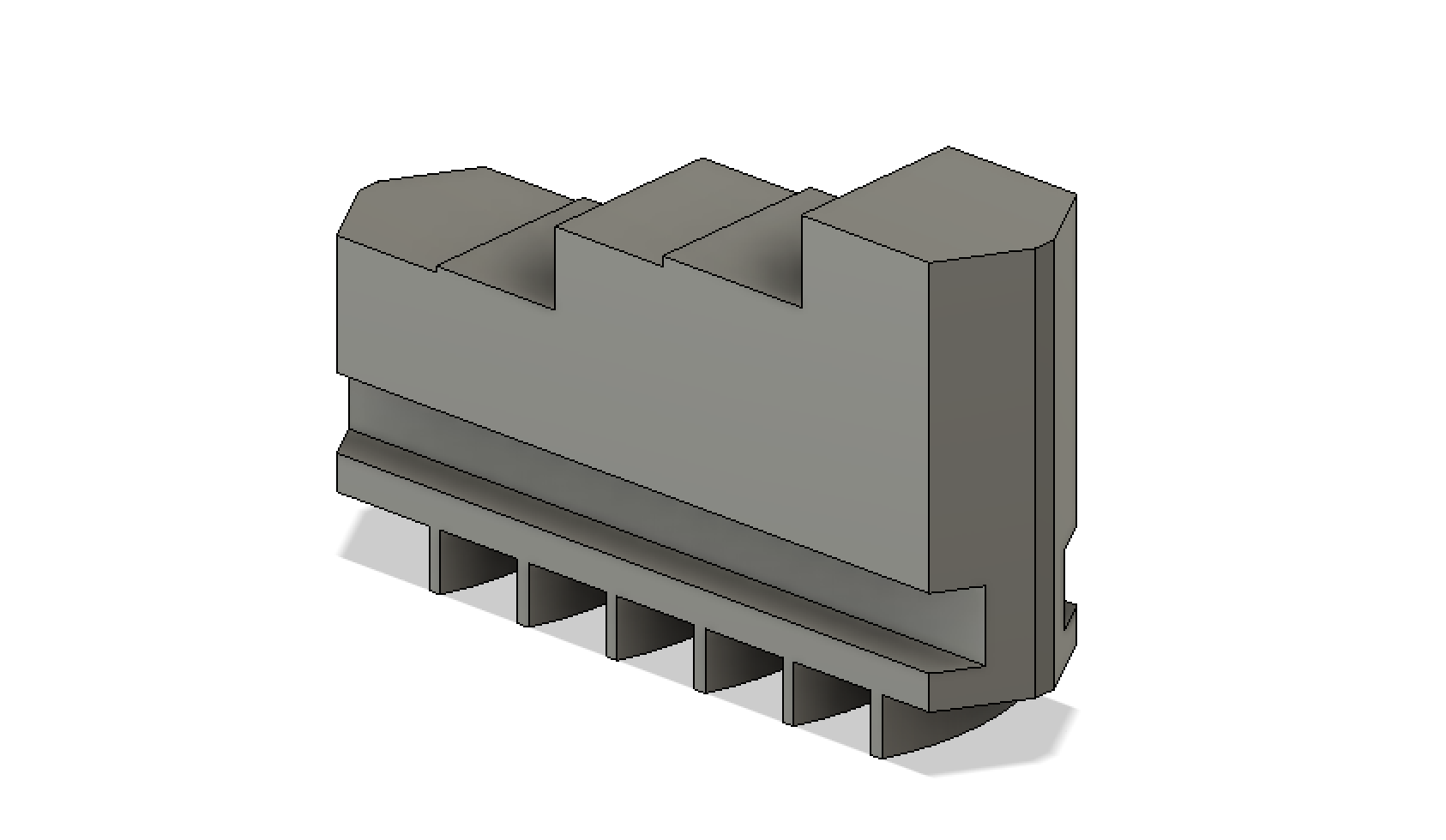

I took a bunch of measurements off of the broken jaw and made a simplified CAD model of the jaw, ignoring features that would later be ground concentric on the lathe.

As it turns out, the side slot, the thickness of the entire jaw, and the scroll tooth geometry are the only really critical dimensions in this entire part, and everything else can be adjusted later through grinding.

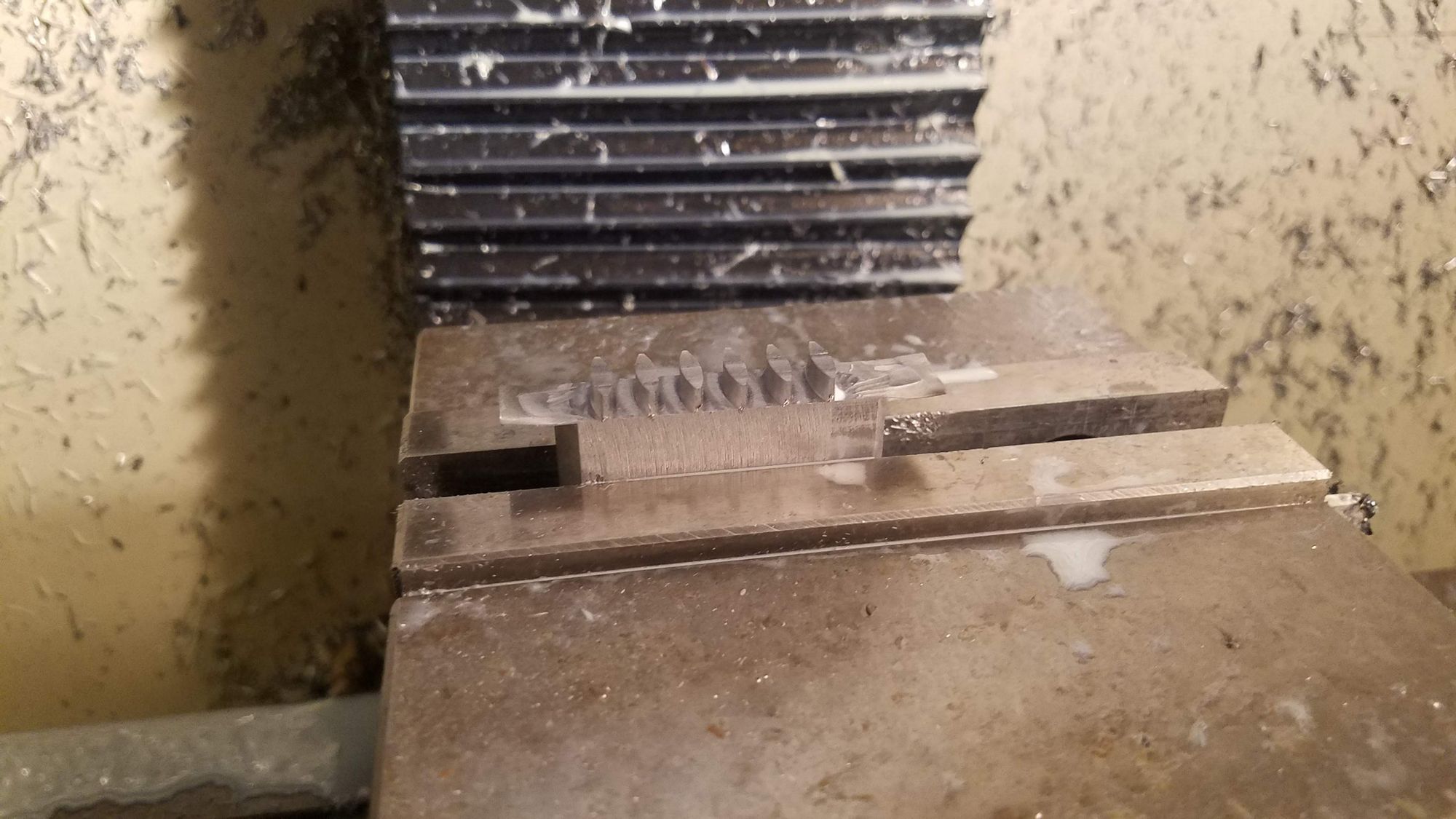

I found nice bar of mystery steel, cut a slab off, and milled it down to the correct thickness.

I cleaned up two of the sides so I could reference them later, and plopped it into the CNC to mill the first set of features.

After checking a couple of dimensions, I flipped it over and cut the scroll teeth.

A quick trip to the mill later, and the jaw was pretty much done!

Unsurprisingly, the chuck no longer runs very true but since it's good enough for most projects, I decided to not grind it and leave it as is. For parts that need to be concentric, there's always the 6 jaw chuck and collets.